Focal points

Under the direction of the two computer science professors Dr Frank Schirmeier and Dr Ulrich Göhner, the IDF focuses on combining mathematical optimisation methods with artificial intelligence applications in the manufacturing environment. The research topics at the IDF are organised into three clusters Digital production plants and data-centric business models, AI-optimised manufacturing processes and innovative sensor technology and large language models and industrial generative AI.

Investments in new technologies boost companies’ innovative prowess and make them more competitive internationally.

As a technology transfer centre at the interface between science and industry, we conduct research into innovative business models. Together with our partner companies, we create the solid basis required for digitalisation and the data economy.

Digitalisation and automation

Digitalising and automating business processes present a major challenge, as efficient solutions are required in response to increasing complexity and the shortage of skilled workers.

The IDF is researching how business processes can be optimised using hybrid systems consisting of classic algorithms and AI – focusing heavily on applying spatial augmented reality and integrating robotics to extensively automate processes. The aim is to reduce the amount of expert knowledge required, relieve the pressure on skilled workers and shorten process times.

Innovative business models

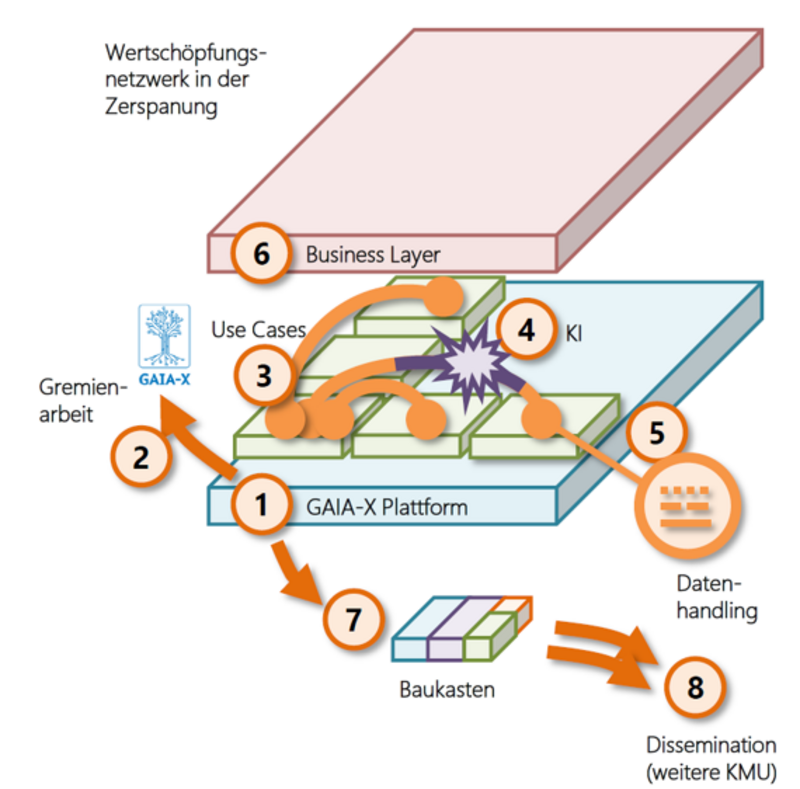

As part of the European cloud initiative GAIA‑X (and funded by the Federal Ministry of Research, Technology and Space), research is being conducted at the IDF into innovative business models made possible by cross-company data exchange.

This broadly spread data exchange generates enormous added value, but it can also violate sensitive trade secrets – which is why the IDF is developing innovative data anonymisation and encryption methods.

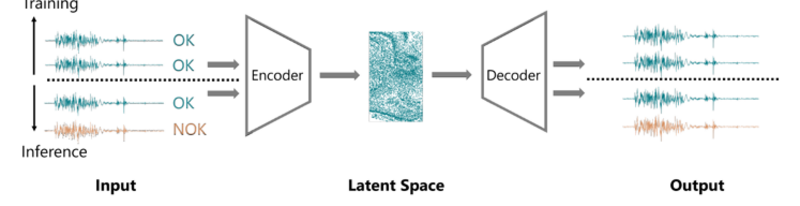

Detecting anomalies

In time-series data streams, such as those generated by industrial sensors, deviations from normal behaviour are often difficult to detect. Assistance can be offered in these cases by the specialised AI methods developed by the IDF in collaboration with well-established manufacturing companies and implemented on site.

Optimisation

Significant efficiency and cost benefits can be achieved by evaluating the data generated using AI methods in business settings.

For specific problems, however, mathematical optimisation algorithms have been shown to find better solutions; in the best case scenario, even the mathematically demonstrably optimum solution.

The IDF’s experts in mathematics and optimisation combine the most appropriate solution methods for each given application scenario.

Correlation and causality

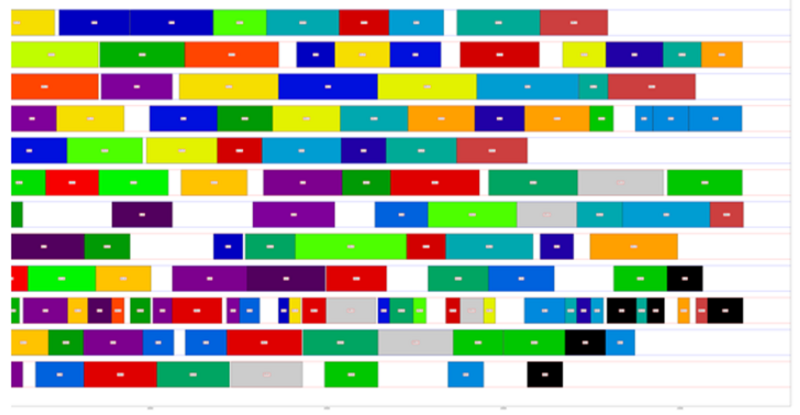

Examining correlations is an established part of exploratory data analysis ¬– helping to identify anomalies in a data set even prior to applying AI methods.

Specifically in the manufacturing environment, identifying genuine causal relationships can generate significant added value: What effect does process parameter X have on quality criterion Y?

To answer this question, the IDF uses highly innovative methods to model causal relationships and then validates the identified causalities in dialogue with manufacturing experts.

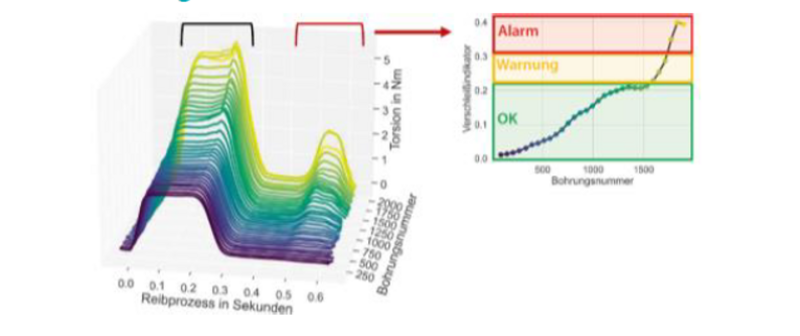

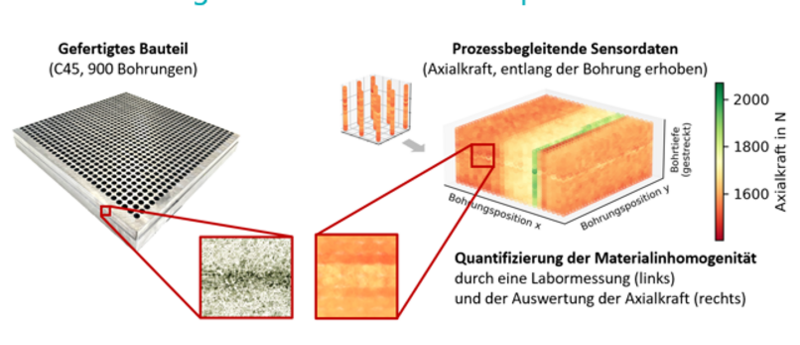

In-process quality control

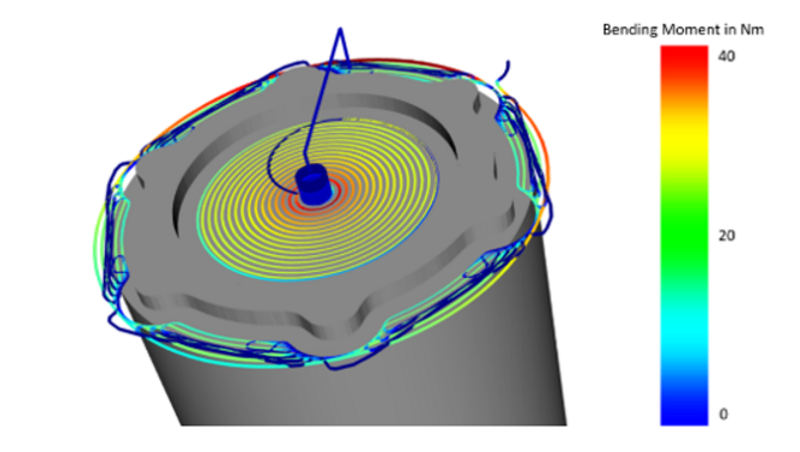

The IDF is conducting research (funded by the Bavarian Ministry of Economic Affairs, Regional Development and Energy) into in-process QC (i.e. quality control based on sensor data during the manufacturing process, rather than downstream) in machining processes. This can drastically reduce time-consuming and costly measuring efforts.

Innovative data collection methods

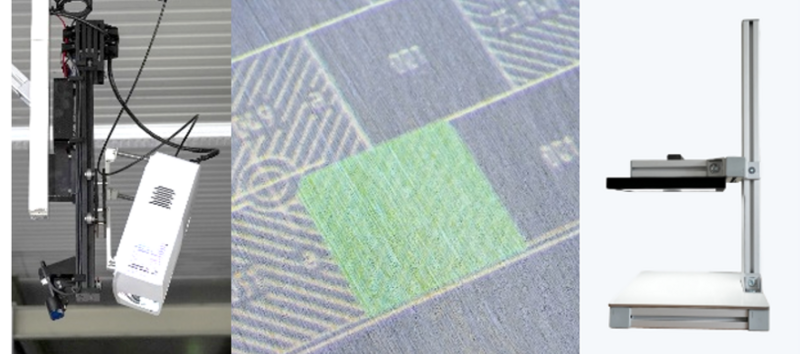

Data scientists and mechanical engineering experts conduct interdisciplinary work hand in hand to channel their combined expertise into the IDF’s models. Developing proprietary data collection methods is often crucial for measuring high-quality target variables for AI models.

Production deviation

By integrating image data into a holistic quality assessment pipeline, optical error images can be evaluated together with data from other sensors, measuring e.g. vibration or force.

Established deep learning architectures are used to evaluate image data, which are combined with innovative methods for reducing dimensions and evaluating the relevant image content.

Artificial intelligence can be used in manufacturing to reduce consumables and energy costs, and to cut waste, while ensuring consistently high manufacturing quality.

The IDF has established itself as a competent research and development partner for prestigious manufacturing companies throughout the Allgäu region, especially in the field of machining.

Generative AI can help humans with providing access to specialist knowledge, automating tasks and finding creative design solutions.

The IDF is involved in various collaborative projects that support regional partners in the process of adapting generative AI. Chatbots can access company documents via RAG Pipelines (= “Retrieval-Augmented Generation”). The IDF is conducting research into locally hosted open-source models, particularly for ensuring the protection of data and trade secrets.

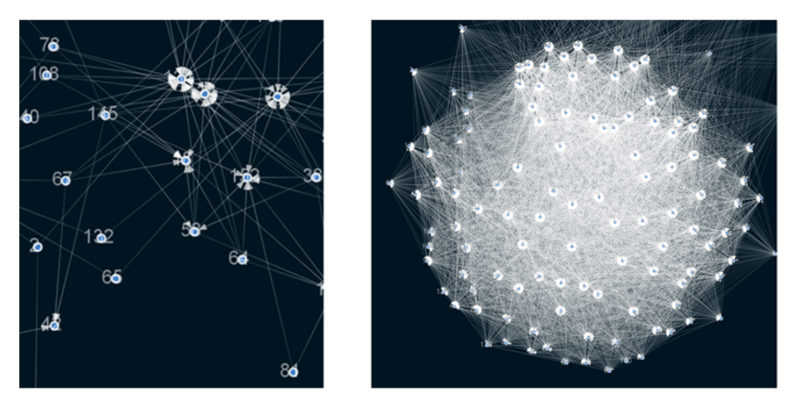

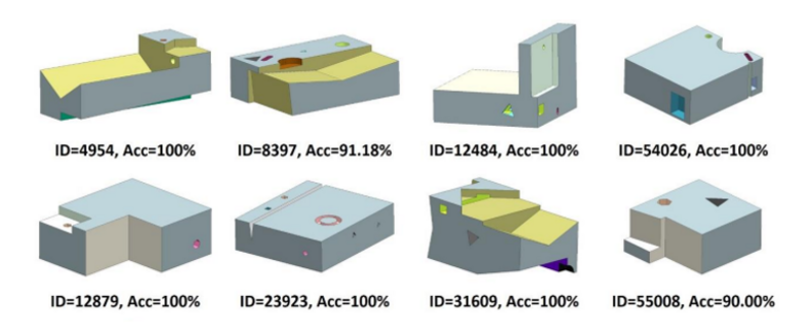

Graph-based neural networks

In addition to transformer-based large language models, specialised AI architectures are also being used successfully. Graph-based neural networks, in particular, can map structures optimally in CAD files

– e.g. for detecting features (e.g. drill holes) in CAD files or for downstream tasks such as estimating costs or workload.

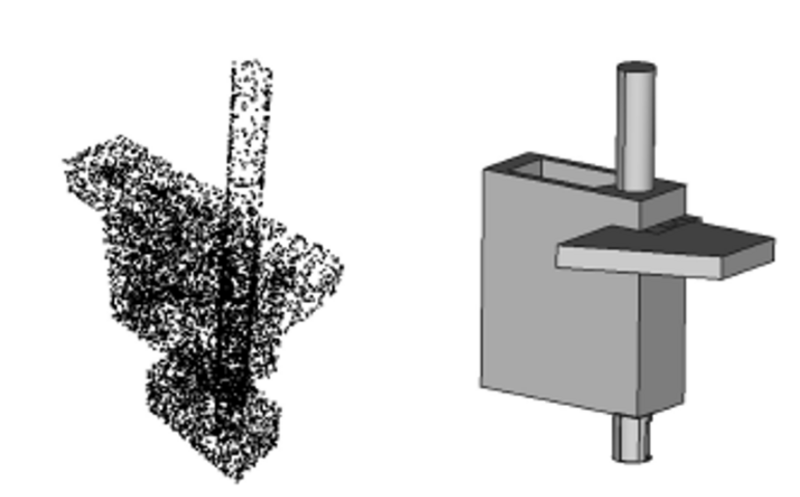

Generative AI

We are also investigating special application scenarios in manufacturing, including automated generation of CAD files and machine control code.

In contrast to commonplace uses of AI to generate images (such as MidJourney, Stable Diffusion, etc.), its creative potential has to be precisely channelled for generating design details in order to ensure adherence to functional and design-related constraints.